Nybro has invested heavily in Industry leading computer software that can simulate many scenarios on CAD models to verify design integrity. These simulations can dramatically reduce the cost of development of new products.

Supporting Documents and Downloads

Videos

Motion Studies

Dynamic assemblies can be designed and studied, identifying problems with clearance, interference, and timing during the design phase. Solutions can be delivered faster than traditional methods of engineering by reducing or even eliminating the need for prototypes.

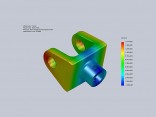

FEA - Finite Element Analysis

Finite Element Analysis or FEA, is a method of calculating the stress occurring inside a component. Scenarios of mechanical restraint and loads are applied to the design, and software will analyse the performance of the design. Areas of critical stress and over design are easily identified. This tool is the most commonly used for answering question like "Is the design strong enough?" or "At what point will the design break?"

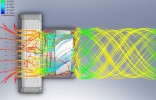

Fluid Dynamics

The flow of air or liquid over or through a design can be analysed easily and quickly. Alternative designs can easily be compared and results shown that identify the efficiency of the design. Whether it is an aerofoil for a high speed aircraft, or a mixing valve inside a plumbing fixture, the software can dramatically reduce the time required to develop efficient designs.

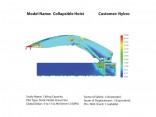

Mould Flow Analysis

Injection moulded parts can be difficult to produce if they are not properly designed. Mould flow analysis will simulate the parameters of injection moulding and determine the injection time. It will identify possible failures in injection design such as short shots, cold spots, and excessive shrinkage.

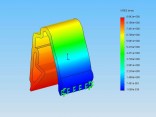

Draft Analysis

Parts that are moulded or cast inside dies need draft on the mould faces to ensure that the parts can be removed from the dies. Complex parts are very hard to check manually for correct draft. The Draft Analysis tool quickly identifies areas where undercuts may occur.

Key Features

Technical Information